IMPORTANT

La Hotline Prodways est réservée exclusivement à l’assistance technique des utilisateurs d’imprimantes Prodways ProMaker.

Vous avez besoin d’assistance technique sur votre imprimante ProMaker ?

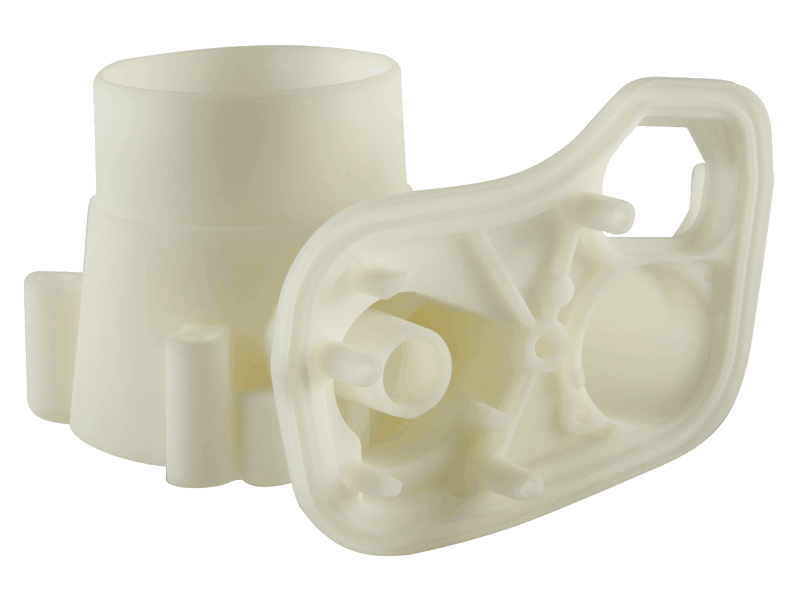

Perfectly adapted for industries such as the medical, electronic, aerospace and automotive markets that require precise and long-lasting models, PLASTCure ABS materials allow you to print high precision parts that are resistant to moisture and temperature.

Specific features of PLASTCure ABS 3000:

PLASTCure ABS 3000 is compatible with all our ProMaker L series printers

*Preliminary data. Performance characteristics of these materials may change according to product application, operating conditions, material combined or end use.