IMPORTANT

La Hotline Prodways est réservée exclusivement à l’assistance technique des utilisateurs d’imprimantes Prodways ProMaker.

Vous avez besoin d’assistance technique sur votre imprimante ProMaker ?

IMPORTANT

La Hotline Prodways est réservée exclusivement à l’assistance technique des utilisateurs d’imprimantes Prodways ProMaker.

Vous avez besoin d’assistance technique sur votre imprimante ProMaker ?

Vous possédez ou exploitez un équipement Prodways, vous souhaitez être dépanné contactez-nous du lundi au vendredi :

Europe, Moyen-Orient, Asie et Afrique – Horaires d’ouverture : 9h-17h (UTC/GMT time +1h)

Amérique du Nord – Horaires d’ouverture : 9h-17h (EST & EDT)

Si vous avez besoin d’information générale ou une question spécifique, contactez nous via la boite CONTACT.

Traditional fixed braces used for teeth straightening are less attractive and uncomfortable because of the use of wires or brackets (often made of metal). Additionally, fixed braces can only be removed by professionals, meaning they cannot be temporarily removed for important occasions or photographs.

With the ultra-customization allowed with 3D printing, dental laboratories developed a new invisible realignment technique through the use of a system of clear, scalable, custom aligners made using digital modeling software and thermoformed directly from 3D printed orthodontic models.

With a daily wearing time of 22 hours and changed every three weeks, the aligners will gradually and smoothly straighten teeth, taking between 6 and 18 months to achieve perfect alignment. The production of aligners requires a perfect communication between the dental laboratory and the orthodontist and perfect precision and quality of the dental models used for thermoforming aligners.

The use of 3D printing solutions is ensuring the repeatability of the whole process, accuracy and quality, unbound to the specific technician expertise. A mass production approach is key for this market since the requested lead time is usually short and up to 24 different models could be needed for the same patient. Therefore, working with high throughput 3D printers are an important requirement to keep good levels of profitability and customer satisfaction.

If you are looking to learn more about how the exploding clear aligner business works, we have the right tool for you.

Prodways worked closely with our partners, dental labs and digital dentistry experts to deliver you the most complete guide to Clear Aligners, covering every topic from the additive manufacturing process to the benefits to benefits to patients and health regulations.

The LD Dental Series printers are already unbeatable machines when it comes to print huge quantities of dental models, therefore the clear aligner production through thermoforming process makes them the natural choice for many labs that look for production speed, part quality and consistency.

With up to 55 dental models printed in 1 hour, no need for printing supports thanks to the granite platform, and no consumables, the ProMaker LD Dental Series make a great combination of print throughput and cost efficiency.

But here at Prodways we wanted to push the limits even further.

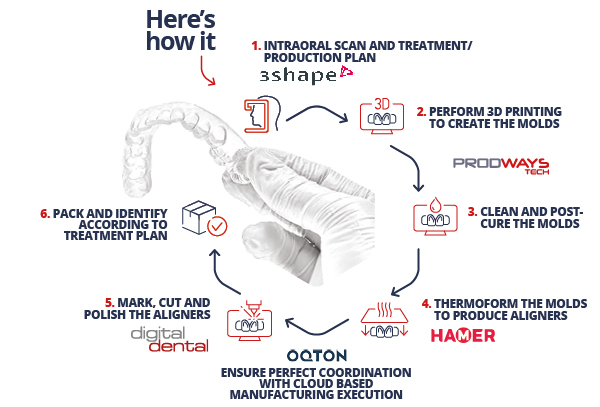

In close collaboration with leading players in the digital dentistry world like 3Shape, Hamer, Digital Dental, and Oqton, we developed a Clear Aligner Ecosystem that will cover every step of the manufacturing cycle of clear aligners: 3D Scanning, Data preparation, Treatment design, 3D printing, Thermoforming, Laser marking and Trimming, and MES software to monitor it all.

This Ecosystem provides a seamless hardware/software integration between each of these steps, with an high level of automatization.

ROI of moving to digital dentistry can be summarized in:

Production throughput and costs forecasts are important indexes to be evaluated when it comes to choose the right machine.

| Production time on a ProMaker LD20 Dental Model 3D Printer | |

|---|---|

| Number of models | 55 |

| Material used | PLASTCure Model 300 |

| Total time @100μm LT (hours) | 1h 02min |

| Time per part (@100µm)67 | 67 secconds |

| Average cost per model | 2.45 € |

The Prodways dental 3D printers feature granite build platforms (perforated platform as option) for increased Z accuracy and reduced post processing time (no support needed), improving productivity and part quality at the same time.

To address the growing need for reliable, high-throughput manufacturing systems for clear aligner production, Prodways has collaborated with the top leaders in digital dentistry to deliver an Ecosystem that provides seamless hardware/software integration. We are proud to work the following network of validated partners:

Would you like to be part of this growing Ecosystem? Contact us today!

Thanks to custom material development and specific machine configuration, we bring the trademark MOVINGLight® accuracy and speed to another level, allowing our customers to print up to 55 thermoforming models in just 1 hour.

Learn more about Absolute Aligner – a revolutionary new resin for the industrial production of clear aligner models!

ProMaker MOVINGLight® printers, unlike other DLP®/Stereolitography printers, use no consumables, making it possible to provide industrial-grade productivity while keeping ownership costs low.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |