IMPORTANT

La Hotline Prodways est réservée exclusivement à l’assistance technique des utilisateurs d’imprimantes Prodways ProMaker.

Vous avez besoin d’assistance technique sur votre imprimante ProMaker ?

Alginate molds: Customized impression trays

Another 3D printing application in the digital dentistry realm is the creation of customized impression trays that truly match the patient mouth’s shape.

Each patient is different, and the use of standardized impression trays always brings a necessary tradeoff between practical convenience, patients comfort and final results.

Contact us for more information!

This is why, as a bridge between the traditional and the digital approach to dentistry, the 3D print of customized dental trays brings all the advantages of a customer-tailored solution to those laboratories that still rely on alginate molds for the final product.

Generally speaking, and this is valid for all the applications, the Return over the investment (ROI) of moving to digital dentistry can be summarized in

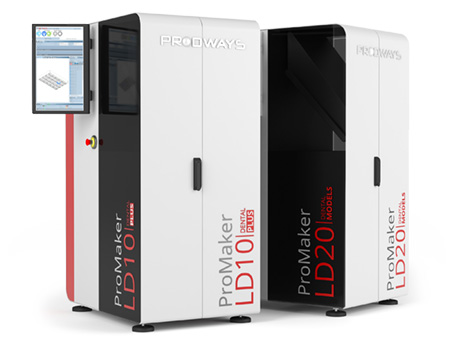

The Prodways dental 3D printers feature granite build platforms (perforated platform as option) for increased Z accuracy and reduced post processing time (no support needed), improving productivity and part quality at the same time.

| Dentist | Lab | Dentist | ||

|

1

Get the scan of the patient mouth using an Intraoral 3D scanner like 3Shape Trios scanner *

|

2

On the scanned dental model, using dedicated CAD software, it’s easy to design custom impression trays, with or without holes, with different holder form, and perfectly tailored on the patient’s mouth shape. **

|

3

Digitally place the 3d impression trays on the build platform of the machine.

Manual, semi-automated or automated nesting tools are available (***) |

4

On the machine, choose the PLASTCure Model material, load the geometries in STL format and print the impression trays.

|

5

The dentist can immediately use the custom trays.

|

Prodways ProMaker LD and L series’ machine profiles and workspaces are available on all the most advanced software for dental application on the market.

Liquid resins for MOVINGLight® printers

Download some of the most interesting case studies shared from our customers, and discover how Prodways technology, innovation and research can help you to boost your business.