IMPORTANT

La Hotline Prodways est réservée exclusivement à l’assistance technique des utilisateurs d’imprimantes Prodways ProMaker.

Vous avez besoin d’assistance technique sur votre imprimante ProMaker ?

In the consumer goods market, additive manufacturing has created new possibilities throughout the phases of functional prototyping, design, tooling, and even through series part production.

Additive manufacturing applications in the consumer product industry are growing in number and adapting to the specific nature and constraints of a rapidly expanding sector with an ever-increasing need to reduce development time.

Prodways has developed a wide range of solutions specifically dedicated to the consumer product industry.

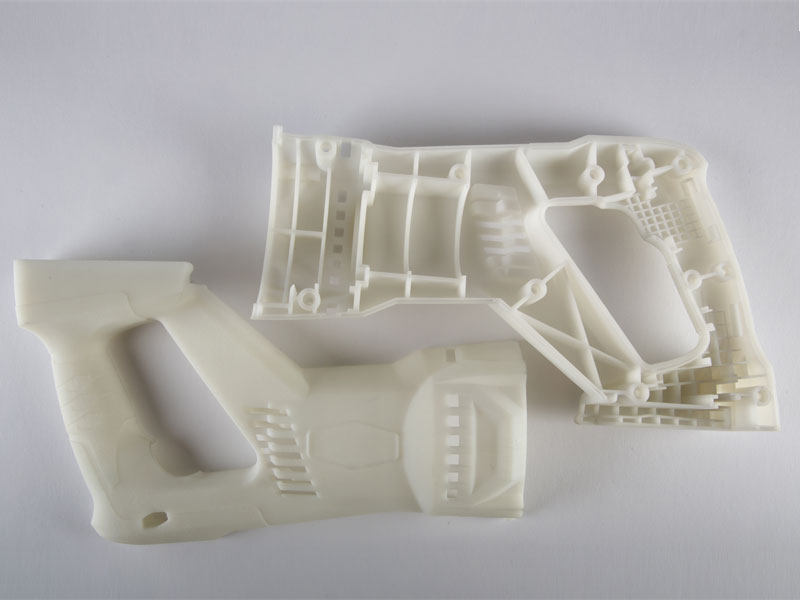

Prodways additive manufacturing solutions allow for the design of parts with complex geometries that are difficult or even impossible to manufacture with traditional processes. 3D printing eliminates the need for tooling and thus allows for a reduction in cost and time for the development of prototypes and durable functional parts. Additionally, this technology helps manufacturers meet the growing need for small series of personalized parts.

Prodways laser sintering technology delivers high productivity to reduce operational costs, excellent thermal stability for optimized mechanical properties, and a very high level of precision and accuracy for your prototypes, functional parts and small series.

Prodways offers a large range of PA12, PA11, TPU and PA6 powder materials and coloring charges to meet the needs for a range of applications for prototypes, functional parts or small series of final parts for household products and appliances, elastomeric midsoles or outsoles, eyeglass frames, gaskets, flexible tubes or fashion parts.

MOVINGLight® technology allows for additive manufacturing of master models used in the development of aluminum molds, with unequaled levels of resolution and complex textures that are difficult to machine with traditional techniques, such as shoe sole molds, for example.

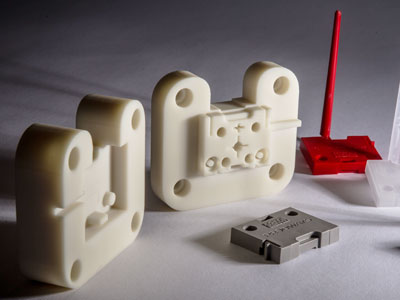

With MOVINGLight® 3D printing technology, you can gain in reactivity and reduce your costs to produce your injection or blow molds to produce plastic parts with the final production material. Materials developed by Prodways to 3D print molds can withstand high pressure and temperature, allowing manufacturers to inject or blow from several dozen to several hundred parts depending on the injected material and the part geometry.

You can now print many iterations of a mold in a very short time to test your prototypes, accelerate new products for market launch, or produce small series of parts with the final production material more quickly and at a lower cost.

For more information on our 3D printing solutions for molding: click here

All Prodways 3D printers offer an open material platform, allowing R&D centers to develop their own applications and push innovation beyond the limits of traditional manufacturing methods or existing technologies.

We also propose high-temperature laser sintering printer configurations, uniquely positioned in their price segment, to work with new high performance materials such as PA6 to develop new and innovative applications for the direct additive manufacturing of final parts.