IMPORTANT

La Hotline Prodways est réservée exclusivement à l’assistance technique des utilisateurs d’imprimantes Prodways ProMaker.

Vous avez besoin d’assistance technique sur votre imprimante ProMaker ?

While the majority of dental models are still produced manually from plaster casting, dentists are increasingly using intra-oral scanners, thereby bringing the workflow into the digital realm, which is expected to result in a sharp increase in the demand for dental models over the coming years.

To meet the increasing demand, dental laboratories need to increase their production capacity while maintaining the necessary precision and quality of their master models.

Contact us for more information!

Thanks to 3D printers, dental laboratories can increase their production capacity and decrease per-unit cost while reducing manual work and improving material efficiency.

Additionally, while traditional stone models are unprecise, 3D printed master models are now allowing unrivaled surface finish and accuracy in all 3 dimensions for bridges and crown work, not depending on technician expertise.

Generally speaking, and this is valid for all the applications, the ROI of moving to digital dentistry can be summarized in

Production throughput and costs forecasts are important indexes to be evaluated when it comes to choose the right machine.

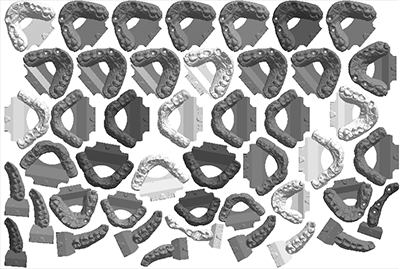

| Production time on a ProMaker LD10 Dental Model 3D Printer | |

|---|---|

| Number of models | 45 |

| Material used | PLASTCure Model 320 |

| Total time @50μm LT (hours) | 4h 45min |

| Total time @100μm LT (hours) | 2h 25min |

| Time per part (@50µm) | 6min 20sec |

| Time per part (@100µm) | 3min 15sec |

| Average cost per model | 2.45 € |

The Prodways dental 3D printers feature granite build platforms (perforated platform as option) for increased Z accuracy and reduced post processing time (no support needed), improving productivity and part quality at the same time.

The standard workflows to get to a master model with the digital dentistry approach are two:

| Dentist | Lab | Dentist | ||

|

1

Get the scan of the patient mouth using an Intraoral 3D scanner like 3Shape Trios scanner *

|

2

Use dedicated CAD software having the scanned dental models as a base, to design prosthetics and implants **

|

3

Digitally place the 3D models on the build platform of the machine

Manual, semi-automated or automated nesting tools are available (***) |

4

On the machine, choose the material, load the geometries in STL format and print the models.

|

5

Now the dentist/ technician can work on the printed model to develop the prosthetics and implants for the customer

|

| Dentist | Lab | Dentist | |||

|

1

Get the dental impression with the standard methods (alginate mold).

|

2

3D Scan the alginate mold with a lab scanner like the 3Shape D2000*

|

3

Loading the 3D mold scan in a dedicated CAD software to create the “positive” model, and to design prosthetics and implants. **

|

4

Digitally place the 3D models on the build platform of the machine

Manual, semi-automated or automated nesting tools are available (***) |

5

On the machine, choose the material, load the geometries in STL format and print the models.

|

6

Now the dentist/ technician can work on the printed model to develop the prosthetics and implants for the customer

|

Prodways ProMaker LD and workspaces are available on all the most advanced software for dental application on the market.

Promaker LD Thanks to the unique combination of high accuracy and productivity of our MOVINGLight® printers,

and to the 3D printing resins specially developed for the dental market,

our customers are able to print prosthetic models for crowns and bridges

with the highest speed/quality ratio in the field.

ProMaker MOVINGLight® printers, unlike other DLP®/Stereolitography printers, use no consumables, making it possible to provide industrial-grade productivity while keeping ownership costs low.